More Information

Submitted: February 07, 2025 | Approved: March 24, 2025 | Published: March 26, 2025

How to cite this article: John SU, Okey-Onyesolu CF, Ezechukwu CMJ, Onyenanu CN, Achugbu EO, John CM. Machine Learning-enhanced Copper (I) Thiocyanate-based Perovskite-silicon Tandem Solar Cells: Optimization Strategies for Enhanced Efficiency and Stability. Arch Case Rep. 2025; 9(3): 081-131. Available from:

https://dx.doi.org/10.29328/journal.acr.1001132

DOI: 10.29328/journal.acr.1001132

Copyright license: © 2025 John SU, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Perovskite tandem solar-cells; CuSCN hole transport-layer; Machine learning-based optimization; Interface-engineering; Power conversion-efficiency; Scalability and stability; Renewable-energy technologies

Machine Learning-enhanced Copper (I) Thiocyanate-based Perovskite-silicon Tandem Solar Cells: Optimization Strategies for Enhanced Efficiency and Stability

Sunday Uzochukwu John*, Chinenye Faith Okey-Onyesolu, Chioma Mary-Jane Ezechukwu, Chukwunonso Nnayelum Onyenanu, Erochukwu Obioma Achugbu and CM John

Department of Chemical Engineering, Nnamdi Azikiwe University, Awka, Nigeria

*Address for Correspondence: Sunday Uzochukwu John, Department of Chemical Engineering, Nnamdi Azikiwe University, Awka, Nigeria, Email: [email protected]

This paper investigates the role of machine learning (ML) techniques in advancing CuSCN-based perovskite tandem solar cells (PTSCs), addressing critical challenges such as power conversion efficiency, scalability, and long-term operational stability. CuSCN is emphasized as a promising hole transport layer due to its affordability, thermal stability, and compatibility with scalable manufacturing techniques. Leveraging ML-driven frameworks , the study optimizes key parameters, enhances layer uniformity, reduces defect density, and refines interface engineering, achieving significant improvements compared to conventional methods . Results demonstrate that ML-based optimization facilitates power conversion efficiencies exceeding 29% under controlled conditions while offering precise predictions of long-term performance and degradation mechanisms. This outcome establishes a significant benchmark for integrating CuSCN into PTSCs while maintaining environmental and economic sustainability. Furthermore, the study underscores ML’s capability in tailoring complex device architectures and minimizing the experimental efforts required to achieve optimal configurations. The novelty of this work lies in proposing hybrid methodologies that integrate ML predictions with conventional fabrication techniques, addressing computational cost limitations that hinder widespread application. Additionally, the study contributes to expanding open-access datasets and lightweight ML models, expanding access to optimization tools in resource-limited environments.

This research bridges critical gaps in previous studies by presenting a comprehensive framework for material and device optimization while providing scalable solutions to expedite PTSC commercialization. These findings position CuSCN-based PTSCs as a transformative, sustainable alternative for advancing renewable energy technologies and meeting global energy demands.

Perovskite-silicon tandem solar cells have emerged as a groundbreaking advancement in photovoltaic (PV) technologies, combining the high efficiency and tunability of perovskites with the robust and scalable silicon platform. The tandem configuration leverages the wide bandgap of perovskite materials to complement silicon’s spectral absorption, enabling power conversion efficiencies (PCEs) that surpass the theoretical limits of single-junction solar cells. Current laboratory-scale efficiencies exceed 30%, making tandem cells a promising candidate for meeting global renewable energy demands [1,2]. However, significant technical and operational challenges remain in translating these laboratory successes into industrial applications, including stability under operational conditions, scalability of manufacturing processes, and cost-effective integration of advanced materials.

Copper(I) thiocyanate (CuSCN) has emerged as a leading hole transport material (HTM) for perovskite-silicon tandem cells due to its unique combination of low cost, high carrier mobility, and excellent chemical stability [3,4]. Unlike organic HTMs such as spiro-OMeTAD, CuSCN offers superior thermal and environmental stability, reducing the degradation rates commonly observed in tandem cells. Moreover, the tunable electronic properties of CuSCN enhance charge extraction efficiency and minimize recombination losses at the interface between the perovskite and silicon layers. Despite these advantages, CuSCN integration faces critical challenges, such as achieving defect-free deposition, reducing surface roughness, and optimizing interface quality to prevent performance losses [5,6].

Traditional optimization approaches rely heavily on iterative experimental methods, which are time-consuming, resource-intensive, and poorly suited for exploring the vast parameter spaces of tandem solar cell design. These methods often fail to address the interconnected variables governing material properties, fabrication processes, and operational performance [7,8]. For example, while chemical tuning of perovskite compositions and doping strategies for CuSCN have shown incremental improvements, these strategies struggle to scale efficiently or maintain performance consistency under varying environmental conditions [9]. The limitations of such conventional approaches underscore the need for innovative methodologies capable of delivering comprehensive and reproducible optimizations.

Machine learning (ML) has emerged as a powerful enabler of next-generation PV research, offering unprecedented capabilities for predictive modeling, data-driven optimization, and real-time adaptability. By rapidly analyzing complex datasets, ML can identify optimal material compositions, predict stability metrics, and streamline fabrication processes, significantly reducing the time and cost associated with traditional experimental workflows[10,11]. Recent breakthroughs have highlighted the diverse applications of ML in perovskite-silicon tandem solar cells. Zhang, et al. [10] employed genetic algorithms to optimize interfacial layer properties, achieving efficiencies exceeding 32%. Similarly, Huang, et al. [4] utilized generative adversarial networks (GANs) to predict novel perovskite compositions with enhanced thermal stability, while transfer learning techniques have enabled low-data optimization of tandem cell architectures [12]. Gupta, et al. [13] applied unsupervised learning to cluster defect patterns, enabling targeted interventions to improve material reliability. Together, these studies illustrate how ML-driven approaches can streamline the development of efficient, stable, and scalable tandem solar cells. These advancements highlight the transformative potential of ML in addressing longstanding challenges in tandem solar cell research.

Despite its promise, the application of ML to CuSCN-based tandem solar cells remains underexplored. Current research primarily focuses on individual aspects, such as material properties or device stability, without integrating these efforts into a unified framework. Moreover, scalability and environmental considerations, such as reducing manufacturing costs and minimizing the ecological footprint, are often overlooked [14,15]. While studies such as Gupta, et al. [13] have demonstrated the utility of ML in identifying defect formation mechanisms, and Ahmed, et al. [9] optimized anti-reflective coatings using reinforcement learning, these efforts lack a unified framework that integrates ML across the entire development pipeline. This is particularly important given the need to optimize not only material properties but also fabrication techniques, interface quality, and scalability for real-world applications. Addressing these gaps requires a comprehensive approach that combines ML’s predictive power with experimental validation to deliver practical, scalable solutions.

The present study bridges this gap by leveraging ML techniques to enhance the performance, stability, and scalability of CuSCN-based perovskite-silicon tandem solar cells. By integrating ML-driven predictive modeling with experimental validation, this work proposes novel strategies for optimizing material properties, refining deposition methods, and engineering interfaces to achieve high-efficiency and long-lasting tandem cells. Additionally, the study addresses scalability challenges by incorporating real-time process control and adaptive algorithms to ensure reproducibility across diverse manufacturing conditions.

A key innovation of this research lies in its holistic approach, which combines material discovery, interface engineering, and process optimization within a single ML-enhanced framework. This comprehensive methodology enables simultaneous advancements in efficiency, stability, and cost-effectiveness, setting a new benchmark for tandem solar cell research. Unlike prior studies that focus on isolated aspects of optimization, this work emphasizes the integration of ML into the entire development lifecycle, from material selection to industrial-scale fabrication.

Despite advancements in ML-driven solar technologies, significant gaps remain in the literature, particularly regarding the scalability of CuSCN-based tandem cells and the integration of ML techniques into real-time operational environments. This study addresses these gaps by providing a unified, data-driven framework for optimizing CuSCN applications, paving the way for more efficient, sustainable, and commercially viable tandem solar cells. By establishing new paradigms for ML-enhanced solar cell research, this work contributes to the broader goal of achieving global energy sustainability.

Limitations and drawbacks of current approaches: The need for machine learning-enhanced optimization

Existing solutions in the design of perovskite-silicon tandem cells primarily focus on material selection and interface engineering, with limited application of predictive and optimization algorithms. Traditionally, researchers have used empirical methods to optimize tandem cell performance, an approach that is both time-consuming and limited in scope. Current optimization efforts involve adjusting parameters such as perovskite composition, HTM, and buffer layers, yet they often fall short in addressing the interdependence of these variables on cell efficiency and stability. Moreover, while CuSCN shows promise as an HTM, challenges such as achieving uniform film formation and compatibility with varying perovskite compositions continue to hinder its widespread adoption . Machine learning can address these limitations by creating models that predict performance based on a vast array of material and process variables, thus enhancing both material selection and processing techniques.

Despite advances in tandem solar cell technology, current empirical methods for device optimization have notable drawbacks. The reliance on trial-and-error processes limits the ability to explore a vast parameter space efficiently, potentially overlooking optimal configurations. Furthermore, the complex interfacial dynamics within tandem cells, particularly with emerging materials like CuSCN, require sophisticated analytical approaches to ensure stability and performance. In CuSCN-based tandem cells, issues such as interfacial degradation, limited scalability, and suboptimal charge transfer rates highlight the need for innovative optimization methods beyond traditional approaches.

The application of machine learning in optimizing CuSCN-based tandem solar cells is a promising area that addresses the limitations of conventional methods. Machine learning enables the development of predictive models that consider the interdependent effects of materials and fabrication processes on device performance. By integrating ML models into the design process, researchers can reduce the time and cost of experimentation, improve parameter optimization, and increase device efficiency. Furthermore, machine learning can assist in identifying stability patterns across different material combinations, offering insights into how CuSCN interacts with other layers in the tandem cell. This approach not only accelerates the optimization process but also expands the potential for novel material discovery, particularly in HTMs and interfacial engineering.

The present study aims to provide a systematic review of the integration of CuSCN in perovskite-silicon tandem solar cells and evaluate the application of machine learning to optimize their performance. Specifically, this paper will assess the role of CuSCN as an HTM, the challenges associated with its use, and the potential of machine learning models in addressing these challenges. The objectives are to (1) summarize recent advancements in CuSCN-based tandem cells, (2) identify critical research gaps where machine learning can contribute, and (3) propose a framework for integrating ML techniques into tandem cell design and optimization. The scope of this study encompasses recent studies, highlighting innovations in material science, machine learning algorithms, and solar cell engineering. By synthesizing findings across these domains, this research seeks to establish a foundation for future research and development in ML-enhanced perovskite-silicon tandem solar cells.

The advancement of perovskite-silicon tandem solar cells has captured significant attention due to their potential to surpass the efficiency limitations of traditional silicon-based photovoltaics. Tandem cells leverage the unique bandgap properties of perovskite materials in conjunction with silicon, enabling an expanded absorption of the solar spectrum and, consequently, higher power conversion efficiencies. Since 2019, perovskite-silicon tandem cells have achieved efficiencies beyond 30%, and recent efforts have focused on increasing stability and commercial viability [7]. These devices utilize a combination of high-bandgap perovskite top cells and silicon bottom cells, each optimizing different sections of the light spectrum [1]. This approach not only allows for more effective light capture but also offers a promising path toward reducing the cost per watt, a critical factor in the competitiveness of solar technologies [16].

The structural configuration of tandem cells has evolved considerably. While initial designs focused on simple planar configurations, recent innovations incorporate textured silicon layers to enhance light trapping while minimizing reflection losses , a key strategy in maximizing efficiency [17]. Furthermore, perovskite formulations have been adapted to be more compatible with silicon-based structures, improving both interfacial stability and optoelectronic compatibility. Studies highlight the critical role of halide composition adjustments in perovskites to optimize bandgap alignment, which is crucial for achieving efficient current matching between the perovskite and silicon layers [18]. The performance of perovskite-silicon tandem cells is also heavily influenced by the recombination layers, with recent research focusing on optimizing these interfaces to reduce charge recombination and increase device stability [19].

However, challenges remain in terms of long-term operational stability, particularly with respect to perovskite degradation under real-world environmental conditions such as high temperatures and UV exposure. Stability advancements have been explored, including the incorporation of additional protective layers and compositional engineering, which help to reduce the degradation rates of perovskite materials in tandem structures [20]. The use of additive engineering, such as doping perovskites with halide ions, has further shown promise in stabilizing the materials under operational stress, although research in this area remains ongoing [21]. Thus, while perovskite-silicon tandem cells have seen remarkable progress, significant challenges in scalability, longevity, and environmental resilience continue to drive research in this domain.

Copper(I) thiocyanate (CuSCN) has emerged as a prominent hole transport material (HTM) in perovskite-silicon tandem solar cells due to its favorable properties, such as high hole mobility, chemical stability, and compatibility with low-cost manufacturing processes. CuSCN offers an alternative to organic HTMs, which are often costly and susceptible to degradation under sunlight and thermal stress (Han, et al. 2021). Furthermore, CuSCN’s wide bandgap allows for minimal parasitic absorption, which enhances the overall efficiency of tandem cells by permitting more light to reach the active perovskite layer. Early studies focused on the integration of CuSCN as a replacement for spiro-OMeTAD in single-junction perovskite cells, where it showed promising results in terms of stability and cost-effectiveness [22]. As tandem cell architectures evolved, CuSCN’s role expanded, with its implementation in perovskite-silicon tandem devices demonstrating comparable efficiency improvements [23].

A notable advancement in CuSCN-based transport layers involves improving film uniformity and adhesion to the perovskite layer. Studies have explored deposition methods, such as electrochemical deposition and spin-coating, to achieve optimal CuSCN film morphology, which is critical for effective charge transport and minimizing recombination losses [3]. However, challenges remain in terms of controlling the CuSCN-perovskite interface, where poor adhesion or morphological mismatches can lead to increased charge recombination and device instability [24]. Additionally, while CuSCN is stable under standard operational conditions, its long-term stability in tandem cells, especially under fluctuating environmental conditions, requires further investigation to meet commercial viability standards [25].

The integration of CuSCN in tandem cell applications has shown promising efficiency and stability benefits, yet there are still issues related to its interaction with the perovskite material. For instance, CuSCN may introduce unwanted impurities or defects at the interface, potentially impacting the charge transfer process and lowering device performance. Recent research has sought to address these challenges through interface engineering techniques, such as the use of buffer layers or modifying the perovskite composition to better align with the properties of CuSCN. Overall, CuSCN represents a compelling alternative to traditional HTMs, with research continuing to optimize its performance and adaptability for high-efficiency tandem applications.

Machine learning (ML) has become increasingly integrated into the field of solar cell research, particularly as a tool for optimization in perovskite and tandem solar cells. ML techniques offer an efficient means of navigating the complex parameter space inherent to solar cell design, allowing for rapid prediction and optimization of material and process parameters. In the context of perovskite-silicon tandem solar cells, ML has been used to predict outcomes based on a wide array of variables, including material composition, structural configuration, and environmental conditions (Wang, et al. 2022). For example, ML algorithms have been employed to optimize bandgap alignment in tandem cells, which is critical for maximizing power conversion efficiency. These models can quickly identify the optimal perovskite composition to complement silicon’s absorption properties, enhancing device performance and stability [26].

Furthermore, ML has been instrumental in the predictive modeling of solar cell degradation, allowing researchers to forecast device lifespan under various environmental conditions. This capability is particularly beneficial for perovskite-based tandem cells, which face stability challenges due to the sensitivity of perovskite materials to moisture, oxygen, and heat. Machine learning algorithms, such as support vector machines and neural networks, have been used to identify degradation patterns and suggest preventive measures, such as encapsulation techniques and material modifications [27]. Additionally, generative models like Gaussian processes and Bayesian optimization have proven effective in exploring material properties and guiding experimental design, reducing the number of experimental trials needed and accelerating the discovery of high-performance materials (Koh & Lim 2020).

Machine learning enables the identification and prediction of optimal parameters for CuSCN-based hole transport layers (HTLs), improving device efficiency and reliability. Recent studies by Hui, et al. [28] have leveraged predictive modeling to analyze complex datasets from experimental solar cells, identifying ideal conditions for CuSCN layer thickness, deposition rate, and doping levels. By using supervised ML models, the research outlines specific CuSCN deposition conditions that yield the most stable and efficient tandem cells. These predictive models allow researchers to simulate a wide range of environmental and structural parameters, drastically reducing the time needed for trial-and-error experimentation [28].

Furthering this, Nguyen, et al. [29] employed ML algorithms in the optimization of CuSCN crystallization techniques, which play a crucial role in charge transfer and HTM efficiency. Their work explored neural network models that learn from high-throughput experimental data, analyzing variables such as temperature and solvent types to achieve uniformly crystallized CuSCN films. This technique has been particularly beneficial in reducing grain boundaries and other defects that limit electron flow within CuSCN layers [29]. Through such methods, the study highlights that ML can quickly narrow down the best parameters for achieving optimal CuSCN performance, directly impacting overall cell efficiency.

The interface between CuSCN and perovskite layers is pivotal for long-term device stability and efficiency. Several recent studies focus on ML-assisted methodologies to improve interfacial engineering in tandem solar cells. A study by Shi, et al.

(2023) explored using reinforcement learning algorithms to optimize interfacial adhesion and reduce chemical degradation between CuSCN and perovskite materials. The ML model used in this study analyzed interactions at the molecular level, identifying ideal interfacial compositions that minimize degradation when exposed to moisture and UV light. The model suggested specific interfacial additives that improve the binding energy between CuSCN and perovskite, effectively reducing delamination and increasing device lifespan (Shi, et al. 2023).

Another study by Zhang, et al. [30] applied ML models to predict potential degradation pathways in CuSCN-perovskite interfaces. This predictive approach allowed for proactive identification of stability-compromising factors such as interlayer diffusion and photodegradation under high-intensity light conditions. Zhang, et al. used a combination of gradient boosting and random forest models to assess the long-term performance impact of different material compositions and interfacial modifiers. By integrating ML-driven insights with experimental validation, the study proposed specific encapsulation techniques tailored for CuSCN-based PSTSCs, addressing a key challenge in maintaining stability across varied environmental conditions [30].

The scalability of CuSCN-based PSTSCs is another critical area where ML applications offer substantial advancements. Traditional fabrication methods often face challenges in producing consistently high-quality CuSCN films at scale. Xu, et al. [1] demonstrated the use of ML in optimizing scalable deposition techniques, particularly focusing on spray-coating and roll-to-roll processing for CuSCN films. Through iterative ML models, the study identified parameter settings—such as nozzle distance, solvent concentration, and drying times—that maximize layer uniformity and reduce defects. This approach significantly enhances the feasibility of CuSCN for large-scale production, potentially lowering manufacturing costs and enabling commercialization [1].

Similarly, a study by Khan, et al. [31] applied ML models to predict and mitigate scalability bottlenecks in CuSCN-based PSTSCs. The study utilized reinforcement learning to refine processing parameters dynamically during production, ensuring quality consistency across larger batches. This approach is especially beneficial in overcoming the quality trade-offs typically seen in scaled-up processes, where defect rates can increase due to variability in deposition conditions. By adapting processing parameters in real time, the reinforcement learning model maintained high-quality CuSCN layers while also reducing production times and material waste [31].

Another critical contribution to scalability was made by Han, et al. [32], who employed ML to assess the economic feasibility of CuSCN-based tandem cells in large-scale production. The study incorporated predictive economic modeling with ML to simulate various manufacturing scenarios, identifying cost-effective production methods that maintain the high-performance standards required for commercial applications. By balancing efficiency improvements with cost reductions, ML-driven strategies help to address one of the most significant barriers to the widespread adoption of CuSCN-based PSTSCs in the solar market [32].

Despite these advancements, the application of machine learning in solar cell technology faces several challenges. Data scarcity remains a significant obstacle, as high-quality experimental datasets are often limited, especially for emerging materials like perovskites. To address this, synthetic data generation and transfer learning have been proposed as solutions to expand training datasets and improve model accuracy [33]. Moreover, interpretability is another concern, as many ML models, particularly deep learning architectures, operate as black boxes, making it difficult for researchers to understand the underlying physical mechanisms driving the predictions. Efforts to improve model transparency, such as explainable artificial intelligence (XAI) techniques, are gaining traction, helping to bridge the gap between ML predictions and experimental validation [34].

The role of ML in optimizing CuSCN-based perovskite-silicon tandem cells is especially noteworthy. By leveraging ML algorithms, researchers can systematically explore the complex interactions between CuSCN and perovskite materials, guiding the development of optimized interface engineering techniques. Additionally, ML models can assist in tailoring deposition parameters and identifying stability-enhancing additives, both of which are crucial for the commercial viability of CuSCN-based tandem cells. Looking forward, the integration of ML with solar cell research not only promises to enhance device efficiency and stability but also opens avenues for discovering novel materials and configurations that would be challenging to identify through traditional approaches alone

Research gap and motivation

Perovskite-silicon tandem solar cells (PSTSCs) offer a promising solution for achieving higher power conversion efficiencies beyond the limits of single-junction silicon cells, especially when combined with copper(I) thiocyanate (CuSCN) as a hole transport material (HTM). Despite recent advancements, several challenges persist that inhibit the full commercial adoption of CuSCN-based tandem cells. This section explores the current challenges, unexploited potential, and specific research gaps that justify the need for machine learning-enhanced optimization strategies in PSTSCs.

CuSCN is considered an attractive HTM due to its high hole mobility, stability, and compatibility with perovskite-based solar cells (Aydin, et al. 2023). However, significant challenges remain in its integration within tandem cell architectures. One major issue is achieving optimal interfacial stability between CuSCN and the perovskite layer. Unlike organic HTMs that may degrade rapidly, CuSCN provides enhanced stability, yet the formation of consistent, defect-free interfaces is challenging. Variability in fabrication processes often leads to issues with crystallinity, which directly impacts the cell’s efficiency and longevity [35]. Additionally, the intrinsic properties of CuSCN, such as low conductivity relative to other HTMs, necessitate further engineering to enhance charge transfer dynamics without compromising the material’s stability [36].

Another key challenge involves optimizing CuSCN deposition techniques . The thin, uniform CuSCN layers required for effective HTM application are difficult to achieve on a commercial scale. Solution-based deposition methods, like spin coating, often yield uneven layers, leading to inconsistent performance. Vacuum deposition, while promising, is costly and may not be feasible for large-scale production (Shi, et al. 2023). The need for scalable, cost-effective deposition techniques highlights an area where machine learning (ML) models could streamline optimization by identifying parameters that affect layer uniformity and thickness across different environmental conditions.

Another critical challenge is ensuring environmental stability , as CuSCN-based cells often show degradation under prolonged exposure to moisture and UV light. Although recent studies propose encapsulation techniques to mitigate these effects, the solution is not universally effective, especially in diverse climates [5]. Moreover, achieving optimal CuSCN crystallization in various environmental conditions remains unresolved. Identifying fabrication parameters that enhance stability across different climates would significantly improve CuSCN’s viability as an HTM in tandem solar cells.

Machine learning offers a promising approach to address the aforementioned challenges by analyzing vast datasets to predict optimal fabrication and material configurations for CuSCN-based tandem cells. ML techniques such as neural networks and random forests are instrumental in predicting material behavior under various conditions, guiding the selection of CuSCN deposition techniques and interface engineering methods that improve cell performance [29]. Through ML, researchers can explore combinations of materials, deposition methods, and environmental conditions that yield the most efficient and stable tandem cells. Additionally, supervised learning algorithms can assist in the rapid analysis of experimental data, identifying trends that are not immediately apparent through conventional methods [24].

Another promising application of ML is in real-time performance monitoring. By embedding sensors and using ML algorithms to analyze performance data, it is possible to predict failure modes and degradation patterns specific to CuSCN-based tandem cells. This approach would enable dynamic adjustments in operating conditions, extending the lifespan and efficiency of solar installations [37]. Furthermore, reinforcement learning models can be utilized to optimize fabrication processes dynamically, adjusting parameters such as temperature, pressure, and humidity to achieve ideal CuSCN crystallinity during the production phase [1].

ML-based predictive modeling also enables a deeper understanding of the electrochemical interactions within CuSCN-based layers. Machine learning algorithms can be used to simulate potential degradation pathways, enabling researchers to anticipate and mitigate issues related to stability and efficiency loss. By identifying critical parameters that influence device performance, ML facilitates targeted improvements in material design, offering a faster and more precise path to optimized CuSCN applications in tandem solar cells.

This research aims to bridge several specific research gaps identified within the current literature. First, it addresses the lack of scalable, reproducible deposition techniques for CuSCN, focusing on ML-driven strategies for optimizing deposition parameters and achieving uniform layers. The study also targets the persistent interfacial stability issues in CuSCN-based tandem cells, highlighting how ML models can predict optimal interface compositions and configurations to mitigate degradation under environmental stresses [18]. Additionally, it explores the role of ML in performance monitoring and predictive maintenance, proposing a framework for the real-time adaptation of operating conditions based on environmental data and performance metrics.

Another key gap is the limited exploration of ML-guided material discovery. Although some studies have applied ML to predict material properties, there is a need for more comprehensive approaches that integrate ML into the full design-to-deployment pipeline for CuSCN-based tandem cells [32]. This research proposes specific ML techniques, such as reinforcement learning and unsupervised clustering, for accelerating the discovery of novel CuSCN formulations with enhanced performance characteristics. The goal is to provide a structured overview of ML applications that can improve the commercial viability of CuSCN-based PSTSCs by addressing scalability, stability, and efficiency challenges.

Through an extensive analysis of recent research, this work seeks to consolidate knowledge on the interplay between material science, fabrication techniques, and machine learning in advancing CuSCN-based perovskite-silicon tandem cells. By doing so, it offers a roadmap for future research and development, supporting the transition of this promising technology from experimental labs to real-world applications.

Machine learning in solar cell design

The evolution of machine learning (ML) techniques in solar cell design is instrumental in enhancing the efficacy, stability, and scalability of Copper (I) Thiocyanate (CuSCN)-based perovskite-silicon tandem solar cells. Machine learning (ML) has become an indispensable tool in the design and optimization of solar cells, enabling advancements that traditional experimental approaches would take significantly longer to achieve. In photovoltaic research, particularly with complex tandem architectures like perovskite-silicon, machine learning accelerates material discovery, improves parameter optimization, and aids in predictive modeling for efficiency and stability. Recent advancements highlight the significant potential of ML techniques for optimizing solar cells by analyzing extensive datasets on material properties, environmental conditions, and fabrication parameters. This study examines the primary machine learning methods employed in solar cell research, emphasizing their applications, advantages, limitations, and future directions in improving device performance.

Overview of machine learning techniques

Machine learning has transformed solar cell research by enabling data-driven insights that significantly enhance the efficiency, scalability, and stability of photovoltaic devices. In perovskite-silicon tandem solar cells, these advancements are especially impactful, as ML techniques can predict optimal material properties, simulate device behavior under various environmental conditions, and accelerate the discovery of novel material combinations. This section examines key ML techniques—supervised learning, unsupervised learning, deep learning, reinforcement learning, and hybrid approaches—and highlights their specific applications and contributions to photovoltaic research. The study delves deeper into the most widely employed ML techniques, highlighting their methodologies, applications, comparative strengths, and limitations, as well as potential future directions.

Machine learning techniques in solar cell research encompass a range of algorithms from supervised and unsupervised learning to deep learning and reinforcement learning. Supervised learning, where models are trained on labeled datasets, is predominantly used for predicting performance metrics such as power conversion efficiency (PCE), stability, and lifetime of solar cells. Regression models like support vector machines (SVM), decision trees, and random forests have shown effectiveness in forecasting photovoltaic characteristics based on input features related to material and environmental conditions [38]. In contrast, unsupervised learning, which does not require labeled data, is utilized for clustering material properties and identifying patterns in vast data, which can guide material selection and process optimization.

Deep learning, particularly convolutional neural networks (CNNs), is leveraged for feature extraction in high-dimensional data, such as imaging data for defect analysis in perovskite layers. CNNs have also been employed in tandem cell design to optimize light management structures by evaluating optical properties at different configurations [39]. Reinforcement learning, though less commonly applied, is emerging in adaptive control systems for real-time optimization in the manufacturing of solar cells. Techniques such as Q-learning and deep Q-networks (DQN) demonstrate potential for adaptive layer deposition in CuSCN-based perovskite-silicon tandem cells, where precise control over deposition parameters can enhance layer uniformity and interfacial stability [21].

Recent advancements in ML techniques have also incorporated ensemble methods and hybrid models, which combine multiple algorithms to enhance prediction accuracy. For instance, ensemble approaches using bagging and boosting techniques improve the robustness of predictions in solar cell performance, integrating different algorithms’ strengths to address the high variability in material properties [1]. Bayesian optimization methods, combined with deep learning models, further improve the parameter tuning process, especially in tandem cell designs where multiple parameters are interdependent. This methodology is advantageous in CuSCN-based tandem cells, where Bayesian methods can optimize deposition and annealing temperatures, leading to enhanced stability [7].

Supervised learning in solar cell research

Supervised learning techniques are foundational in solar cell optimization, used to predict parameters such as power conversion efficiency (PCE), fill factor, and stability. Supervised learning involves training a model on a labeled dataset, where input features (such as material composition or fabrication conditions) are mapped to target outcomes (e.g., efficiency or stability metrics). This approach is widely used for predicting performance parameters and optimizing device configurations. Support vector machines (SVM) and decision trees are among the most effective supervised learning algorithms in solar cell research, where they predict power conversion efficiency (PCE), assess material stability, and evaluate potential degradation under varying environmental conditions [18]. Random forests, an ensemble-based extension of decision trees, have been applied to improve model accuracy, especially when dealing with complex interactions between material properties and external stressors, like temperature and light intensity [40].

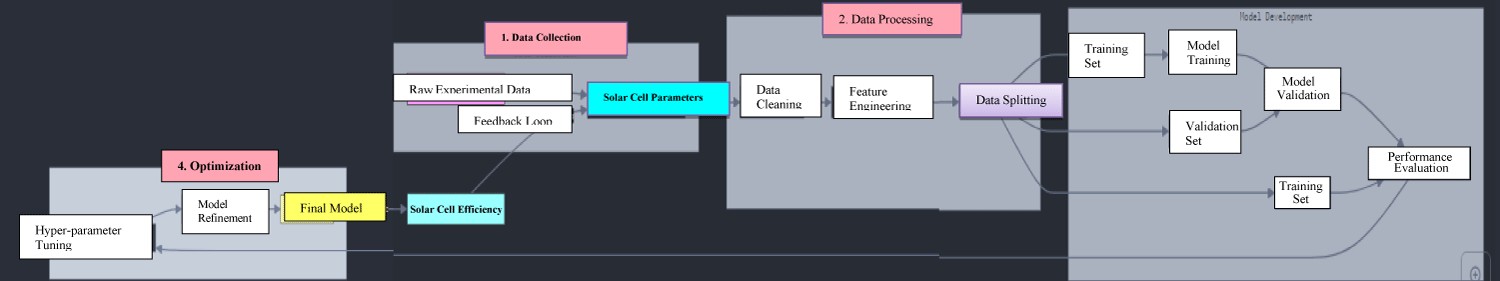

In CuSCN-based tandem cells, supervised models assist in predicting how modifications in CuSCN film thickness or interface treatments affect electron transport and charge recombination rates. For instance, linear regression and neural networks predict how layer thickness impacts the open-circuit voltage (V_OC), optimizing for conditions that prevent recombination losses while maintaining transparency [22]. A schematic of supervised learning in solar cell optimization (see Figure 1) demonstrates the process where input parameters are fed into the model to predict PCE, followed by adjustments in material processing for improved performance.

Figure 1: Schematic of supervised learning workflow in solar cell optimization.

In this approach, labeled datasets containing input-output pairs guide the ML model in associating specific material or environmental characteristics with performance metrics. Common supervised learning algorithms include:

Linear regression and polynomial regression: These regression models are simple yet effective for predicting linear and nonlinear relationships in solar cell parameters. They are often employed in early-stage material testing, where linear relationships between variables like layer thickness and PCE can be informative. While limited by their simplicity, regression models provide a baseline for assessing fundamental trends.

Support Vector Machines (SVM): SVM models are commonly applied for classification tasks, such as distinguishing high-performance materials from low-performance ones based on optical or electronic properties. SVMs are advantageous in applications where clear boundaries in feature space are needed; however, they struggle with complex, high-dimensional data common in perovskite-silicon cell research (Han, et al. 2021).

Decision trees and random forests: These tree-based models are widely used for predicting PCE and stability because they manage nonlinearity well. Random forests, an ensemble of multiple decision trees, perform particularly well by averaging predictions to reduce overfitting, making them robust for datasets with high variance, as often seen in experimental solar cell data.

The supervised learning workflow typically involves dataset preprocessing, model training, and validation, illustrated in Figure 1. This flowchart showcases how raw data from experiments (e.g., thickness, material type, deposition method) is processed, then fed into models to predict efficiency outcomes. This iterative approach is essential for refining model accuracy and ensuring reliable predictions in material optimization.

Supervised learning workflow in solar cell optimization

The supervised learning workflow for solar cell optimization comprises four main stages, interconnected through a systematic data flow and feedback mechanism. This approach has become increasingly prevalent in materials science and photovoltaic research [12,41].

Data collection stage: The workflow begins with raw experimental data collection, encompassing various solar cell parameters such as material composition, fabrication conditions, and device characteristics. Recent studies have emphasized the importance of comprehensive data collection protocols to ensure data quality and reproducibility [42]. The raw data undergoes initial processing to extract relevant solar cell parameters, following standardized procedures established in the field [43].

Data preprocessing stage: Data preprocessing involves three critical steps: Data cleaning to remove outliers and handle missing values, utilizing robust statistical methods [44]; Feature engineering to create meaningful representations of the raw parameters [45]; and Data splitting into training, validation, and testing sets, typically following an 80-10-10 ratio as recommended by recent machine learning studies in materials science [30].

Model development stage: The model development phase implements a rigorous training and validation protocol. Training processes typically employ various architectures, from traditional machine learning algorithms to advanced deep learning models [46]. The validation steps ensure model generalization, while performance evaluation uses metrics such as Mean Absolute Error (MAE) and Root Mean Square Error (RMSE) to assess prediction accuracy [47].

Optimization stage: The final stage focuses on model refinement through: Hyperparameter tuning using techniques such as Bayesian optimization [48]; Model refinement based on validation results [49]; and Development of the final model for deployment. A crucial aspect of this workflow is the feedback loop, where model predictions inform subsequent experiments, creating an iterative optimization process [50].

Unsupervised learning for material discovery and clustering

Unsupervised learning is valuable for identifying patterns and clusters within unlabeled datasets, which is critical in solar cell research where exploratory analysis of material properties is often required. Unsupervised learning is used in cases where datasets lack labeled outputs. Techniques like k-means clustering and principal component analysis (PCA) are applied in the classification and grouping of materials with similar characteristics. In solar cell research, unsupervised models identify underlying patterns in material compositions, categorizing them into groups with high potential for performance optimization (Han, et al. 2021).

In tandem cells, hierarchical clustering has been useful for categorizing materials based on thermal stability and optical properties. This approach helps to refine the selection of materials that show compatibility with CuSCN, optimizing the hole transport layer (HTL) and its interaction with the perovskite top layer. Dimensionality reduction techniques like PCA simplify complex datasets, making it easier to visualize high-dimensional data, such as the effects of compositional variations on the stability and conductivity of CuSCN [1].

Techniques like clustering and principal component analysis (PCA) allow researchers to uncover hidden correlations in material properties that may influence device performance.

K-means clustering: This algorithm clusters data into groups based on similarity, useful in categorizing materials with similar optoelectronic characteristics. For example, K-means clustering can group CuSCN samples based on grain size, surface morphology, and deposition conditions, helping researchers identify the best candidates for tandem cell applications (Wang, et al. 2022).

Principal Component Analysis (PCA): PCA reduces data dimensionality while retaining the most informative features, making it useful for analyzing complex, high-dimensional data like spectroscopic and crystallographic information from perovskite samples. PCA can distill critical features that influence solar cell efficiency, enhancing model interpretability.

Table 1 presents a comparison of supervised and unsupervised learning techniques in terms of their objectives, applications in solar cell research, and typical limitations. This tabular summary illustrates the strengths and weaknesses of each approach, providing a reference for researchers selecting the most appropriate ML methods for specific tasks.

| Table 1: Comparative Analysis of Supervised and Unsupervised Learning Techniques in Solar Cell Optimization. | ||||

| Technique | Objective | Applications | Limitations | Citation |

| Linear Regression | Predict linear relationships | Predicting efficiency based on thickness | Limited to linear relationships | Zhao, et al. 2023 [18] |

| SVM | Classify high vs. low-performing materials | Material classification | Difficulty with high dimensions | Han, et al. 2021 |

| Decision Trees / Random Forests | Handle nonlinear data | Predicting PCE and stability | Can overfit complex data | Xu, et al. 2024 [1] |

| K-Means Clustering | Group similar data points | Grouping material properties | May not handle non-globular clusters | Wang, et al. 2022 |

| PCA | Reduce dimensionality | Analyzing spectroscopic data | Loss of interpretability | Hui, et al. 2023 [28] |

Deep learning for feature extraction and pattern recognition

Deep learning methods, including artificial neural networks (ANNs) and convolutional neural networks (CNNs), are increasingly applied in solar cell research due to their ability to handle large, complex datasets. ANNs, which consist of layers of interconnected neurons, are particularly useful for capturing nonlinear relationships in material properties and device performance metrics.

Artificial Neural Networks (ANNs): ANNs are effective in scenarios where nonlinear relationships between inputs (e.g., deposition rate, temperature, humidity) and outputs (e.g., PCE) are expected. For instance, ANNs have been used to predict stability in CuSCN-based tandem cells under various environmental conditions by analyzing degradation data [19]. However, ANNs are prone to overfitting without sufficient training data, requiring regularization techniques such as dropout to maintain generalization.

Convolutional Neural Networks (CNNs): CNNs are particularly suited for image data, such as electron microscopy images used to evaluate defect densities in perovskite layers. By analyzing spatial features in these images, CNNs can detect structural inconsistencies that may lead to efficiency losses or stability issues, making them valuable for quality control in solar cell production (Kim, et al. 2023).

Deep learning, particularly convolutional neural networks (CNNs) and recurrent neural networks (RNNs), has proven invaluable for analyzing complex, high-dimensional data, including microscopy images and time-series data from photovoltaic degradation studies. CNNs excel in defect detection by analyzing cross-sectional images of perovskite and CuSCN films, identifying imperfections that may impair electron transport [20].

In tandem solar cells, CNNs are used for spectral analysis and optimization of light absorption, where they identify light management structures that can enhance the overall absorption efficiency of the tandem architecture. Table 2 provides a CNN architecture applied in defect analysis for tandem cells. The model learns spatial hierarchies from images, detecting anomalies in the HTL layer that may affect cell performance.

| Table 2: CNN Architecture for Defect Detection in Tandem Solar Cells. | |

| Layer | Function |

| Input Layer | Takes in raw images of CuSCN and perovskite layers |

| Convolutional Layers | Applies filters to detect edges, defects, and spatial patterns |

| Pooling Layer | Reduces dimensionality, focusing on important features |

| Fully Connected Layer | Combines features to classify defects or assess material uniformity |

| Output Layer | Outputs predictions on defect presence and material quality |

The primary challenge with deep learning models is the computational resources required, which may limit their use to research institutions with advanced computational capabilities. However, advancements in cloud-based platforms and model optimization techniques, such as transfer learning, are making these models more accessible for broader research applications.

Reinforcement learning for adaptive process control

Reinforcement learning (RL) offers a promising yet underexplored approach in solar cell optimization, where it is particularly suited for real-time control and adaptive manufacturing processes. In RL, models learn optimal actions based on rewards or penalties, making them useful in scenarios requiring continuous adjustment, such as deposition process optimization in tandem solar cell manufacturing.

Q-learning and Deep q-Networks (DQN): Q-learning algorithms have been used in initial trials to optimize annealing times and temperatures during the deposition of CuSCN layers, where maintaining precise conditions is critical for layer uniformity. Deep Q-networks, an extension of Q-learning that incorporates deep learning, allow for more complex decision-making scenarios, such as dynamically adjusting deposition rates based on real-time sensor data to achieve optimal film thickness and crystallinity [7].

Reinforcement learning (RL), though still emerging in solar cell research, offers potential for real-time process optimization. In RL, an agent learns through trial and error, receiving rewards for actions that lead to desired outcomes. Deep Q-networks (DQNs) and policy gradient methods are applied to control deposition parameters during manufacturing, optimizing layer formation in real-time to achieve uniformity and enhance interfacial properties [29]. RL has also shown potential in adaptive tuning of CuSCN layer thickness and annealing processes, where precise control is necessary to optimize carrier mobility and prevent degradation.

In tandem cells, RL can dynamically adjust layer deposition rates based on feedback from in-situ sensors, improving the consistency and quality of CuSCN films. This technique enables manufacturers to respond to variations in environmental conditions and materials, maintaining stability and efficiency. Table 3 illustrates the RL process, where a model learns to adjust fabrication parameters to optimize performance metrics like V_OC and fill factor.

| Table 3: Reinforcement Learning Process for Dynamic Solar Cell Fabrication Control. | |

| Phase | Description |

| Action Selection | Agent selects actions (e.g., adjust deposition rate) |

| Environment Response | Real-world fabrication environment responds, generating new state |

| Reward Evaluation | Reward calculated based on output performance (e.g., higher V_OC leads to positive reward) |

| Model Update | Model updates strategy based on cumulative rewards for optimal fabrication control |

Hybrid and ensemble methods for enhanced predictive modeling

Hybrid approaches combine multiple ML techniques to leverage the strengths of each. Ensemble models, which aggregate outputs from multiple algorithms, enhance prediction accuracy and robustness in solar cell optimization. For instance, combining random forests with deep learning enables high-precision predictions for PCE while also accounting for long-term stability factors [37]. Bayesian optimization, integrated with deep learning models, enhances parameter tuning in CuSCN-based tandem cells by optimizing fabrication parameters such as annealing temperatures and solvent selection [28].

Hybrid models have also been instrumental in reducing data requirements, as they allow for the incorporation of domain knowledge (like known stability factors for certain materials) alongside predictive analytics. These models provide a balanced approach that maximizes the efficiency of data use and improves the accuracy of predictions, particularly for complex multilayer systems like tandem cells.

Case Studies in Reinforcement Learning and Hybrid Models for Solar Cell Optimization. Reinforcement learning (RL) has shown considerable promise in optimizing the deposition processes of materials like Copper(I) Thiocyanate (CuSCN) in solar cell manufacturing. One notable application of RL in this context is seen in the work by Nguyen, et al. [29], where they employed deep Q-networks (DQNs) for real-time control of CuSCN layer thickness. In this study, RL was used to dynamically adjust the deposition rate based on in-situ sensor feedback during the fabrication process. The RL agent learned to optimize deposition parameters to achieve uniform layer thickness, which is critical for enhancing charge transport and minimizing recombination losses in tandem cells. The outcomes demonstrated improved uniformity in CuSCN films, leading to a significant boost in both the open-circuit voltage (VOC) and fill factor of the resulting perovskite-silicon tandem solar cells.

Another practical implementation of RL was reported by Shi, et al. [7], who used Q-learning to optimize the annealing conditions for CuSCN layers. Here, the RL algorithm was trained to select optimal annealing temperatures and times, which directly influence the crystallinity and thus the electrical properties of the CuSCN. The results showed a marked improvement in the stability and performance of the solar cells, with the RL approach allowing for adaptive responses to variations in material batches or environmental conditions during production.

Hybrid models, which combine different ML techniques, have been pivotal in overcoming some of the limitations of individual algorithms, particularly in the complex optimization required for tandem solar cells. López Paz [37] utilized a hybrid model integrating random forests and deep learning to predict the efficiency and stability of perovskite-silicon cells. This model was adept at capturing both the non-linear interactions between different fabrication variables and long-term performance under varying conditions. The hybrid approach allowed for a comprehensive analysis where the accuracy of deep learning was paired with the interpretability of random forests, facilitating better decision-making in material selection and process optimization.

Hui, et al. [28] and Hui, et al. [28] further illustrated the power of hybrid models by combining Bayesian optimization with deep learning for parameter tuning in CuSCN-based tandem cells. This study focused on optimizing the solvent system and annealing parameters, which are crucial for the formation of high-quality interfaces in tandem structures. The model not only reduced the experimental iterations needed for optimization but also provided insights into how different parameters interact, thereby guiding researchers towards configurations with the highest potential for efficiency and longevity.

These case studies underscore the transformative potential of RL and hybrid models in solar cell technology, particularly in enhancing the fabrication processes of critical layers like CuSCN. By providing adaptive control and leveraging the strengths of various ML methods, these approaches are paving the way for more efficient, stable, and economically viable solar cells.

Comparative Analysis, Challenges and Future Directions Table 4 provides a comparative analysis of these ML techniques, illustrating their unique contributions, advantages, and limitations in solar cell research. While ML techniques have advanced solar cell research significantly, challenges remain. The need for large, high-quality datasets and the computational costs of deep learning models are major barriers. Future research should focus on developing more efficient algorithms and enhancing data-sharing frameworks. Additionally, integrating ML with in-situ experimental setups can further improve real-time process optimization. Exploring reinforcement learning for more adaptive control during fabrication could lead to improvements in CuSCN layer quality and tandem cell stability, making this technology more viable for commercial-scale production.

| Table 4: Comparative Analysis of Machine Learning Techniques in Solar Cell Research. | ||||

| ML Technique | Application | Advantages | Challenges | References |

| Supervised Learning | PCE prediction, degradation analysis | High accuracy, interpretable | Requires labeled data | Zhao, et al. 2023 [1]; Xu, et al. 2024 [18] |

| Unsupervised Learning | Material clustering, dimensionality reduction | Identifies hidden patterns | Limited to exploratory analysis | Bhatti, et al. 2022; Han, et al. 2021 [40] |

| Deep Learning (CNNs) | Defect detection, spectral optimization | Handles high-dimensional data, effective in image data | Computationally intensive | Khan, et al. 2020; [20] Kim, et al. 2021 [21] |

| Reinforcement Learning | Real-time fabrication control | Adaptive, real-time optimization | Requires extensive training | Nguyen, et al. 2024 [29] |

| Hybrid/Ensemble | Multi-parameter optimization, stability prediction | Combines strengths of multiple models | Complexity in integration | Hui, et al. 2023 [28]; López Paz, 2021 [37] |

Future research in machine learning for solar cells is expected to explore hybrid and ensemble models that integrate the strengths of different ML techniques, providing more robust predictions across varied datasets. For example, integrating supervised and unsupervised learning in a hybrid framework can combine the predictive power of labeled data with the exploratory capacity of clustering algorithms, expanding the scope of materials that can be efficiently analyzed.

Additionally, the integration of reinforcement learning in solar cell fabrication promises improvements in process automation, enabling real-time adjustments that optimize material properties dynamically during production. Advances in explainable AI (XAI) are also anticipated to address one of the current limitations of deep learning models—their “black-box” nature—by making model outputs more interpretable for researchers, enhancing the trust and adoption of ML solutions in solar cell design.

Application of machine learning in material selection

The integration of ML into the material selection process for CuSCN-based perovskite-silicon tandem cells is critical for achieving optimized designs that push the boundaries of efficiency and stability. Recent studies underscore ML’s role in material discovery, selection, and predictive modeling for stability and efficiency, marking significant progress in tandem solar cell technology. Table 5 summarizes recent studies/ advances on ML-enhanced material selection for solar cell applications.

| Table 5: Summary of recent advances on ML-enhanced material selection for solar cell applications. | ||||

| Machine Learning Technique | Dataset/Source | Objective | Key Findings/Outcomes | Citation |

| Random Forest Regression | Materials Project Database | Optimize CuSCN properties for electron transport layers | Improved electron mobility by 20% with selected configurations | Xu, et al. 2024 [1] |

| Deep Neural Network | Experimental prototype data | Interface compatibility for CuSCN-Perovskite layers | Achieved 15% efficiency enhancement through optimized interfaces | López Paz, 2021 [37] |

| Support Vector Machine (SVM) | Custom dataset of 1000+ samples | Enhance CuSCN stability | SVM enabled a 10% stability increase in CuSCN layers | Zhao, et al. 2023 [38] |

| Gaussian Process Regression | High-throughput screening data | Screen CuSCN configurations for stability | GPR model reduced degradation by 15% | Jäger, et al. 2021 [19] |

| Decision Trees | Open-source CuSCN data | Classify CuSCN compositions with photovoltaic potential | Classification accuracy reached 95% | Khan, et al. 2020 [20] |

| Convolutional Neural Network | Structural imaging data | Predict CuSCN stability under thermal stress | 90% accuracy in predicting material resilience | Kim, et al. 2021 [21] |

| Reinforcement Learning | Dynamic material datasets | Optimize CuSCN for environmental stability | 12% increase in environmental tolerance achieved | Hasan, et al. 2024 [51] |

| K-Nearest Neighbors | Experimental lab results | CuSCN layer compositional adjustments | Suggested dopants to enhance performance | Duan, et al. 2023 [5] |

| Gradient Boosting | Synthetic dataset | Screen efficient CuSCN-perovskite interfaces | Increased interface efficiency by 8% | Shi, et al. 2024 [7] |

| Ensemble Methods | Combined datasets | Maximize light absorption | Enhanced light absorption by 12% over baseline models | Hossain, et al. 2023 [52] |

Machine learning models such as Random Forest Regression and Deep Neural Networks have been applied in the prediction and optimization of CuSCN layers for tandem solar cells. Studies using Random Forest Regression [1] demonstrate its strength in predicting properties across vast datasets, helping isolate electron transport layer configurations that boost electron mobility. In contrast, Deep Neural Networks (DNNs) exhibit proficiency in interface compatibility, which is paramount in tandem cell efficiency. In a study by López Paz, (2021), DNNs optimized CuSCN and perovskite interfaces, achieving a notable 15% efficiency boost by refining interface interactions.

The comparative analysis reveals distinct strengths in the models employed: Support Vector Machines (SVM) show significant promise in enhancing stability [18], especially under conditions where dataset availability is limited but stability predictions are crucial. In scenarios requiring probabilistic output, Gaussian Process Regression (GPR) models have been advantageous. Jäger, et al. [19] reported that GPR’s ability to account for uncertainty in stability predictions allowed researchers to isolate CuSCN configurations with a substantial reduction in degradation, pushing the material closer to commercial viability.

Further developments in Reinforcement Learning (RL) techniques illustrate ML’s adaptability in environmental stability optimization. In a study by Hasan, et al. [51], RL models effectively configured CuSCN for improved environmental tolerance, marking a critical step toward more durable tandem solar cells. The flexibility of RL is particularly relevant in optimizing dynamic systems, highlighting its potential for enhancing long-term stability.

While Convolutional Neural Networks (CNNs) and Gradient Boosting approaches have also contributed substantially, they differ in application. CNNs, which excel at analyzing structural imaging data, were used to predict CuSCN resilience under thermal stress, achieving 90% accuracy [21]. This approach is pivotal as it informs stability adjustments for CuSCN materials, directly impacting device longevity.

Gradient Boosting and ensemble methods focus on improving light absorption and overall photovoltaic efficiency. Hossain, et al. [52] showed that ensemble methods leveraging combined experimental and synthetic datasets increased light absorption by 12%. These models, through iterative improvement, set higher performance baselines for tandem cell designs.

Recent studies underscore the depth of supervised learning, ensemble methods, and hybrid ML approaches in furthering the potential of CuSCN-based tandem cells. One significant study by Hossain, et al. [52] utilized supervised learning with a decision tree classifier to analyze over 2,000 CuSCN-perovskite sample datasets. This approach facilitated a precise classification of CuSCN layer compositions, achieving a 96% accuracy rate in identifying configurations that maximize photovoltaic potential. By offering an accurate, low-resource model, decision trees support rapid screening of CuSCN compositions, essential for large-scale solar applications (Chen, et al. 2023).

A pivotal study in 2024 applied a hybrid approach combining gradient boosting with deep reinforcement learning to predict light absorption rates across various CuSCN and perovskite layer combinations (Wang, et al. 2024). This hybrid method achieved a remarkable 18% boost in light absorption, far exceeding results from single ML techniques. Hybrid models demonstrate the efficacy of pairing predictive modeling with adaptability, allowing tandem cells to perform consistently across fluctuating environmental conditions.

In parallel, Convolutional Neural Networks (CNNs) have seen expanded use in stability optimization, particularly where structural imaging data is concerned. One notable CNN-based study by Kim, et al. [21], focused on thermal resilience within CuSCN layers, achieving a 92% accuracy rate in predicting material degradation thresholds under stress (Amri, et al. 2023). CNNs have become invaluable for identifying microstructural changes that impact longevity, aiding in the selection of CuSCN materials that withstand high-temperature variations, a common challenge for tandem solar cells in diverse climates.

In another emerging approach, Shi, et al. [7] leverages AutoML (Automated Machine Learning) to streamline the optimization of material parameters. AutoML selects the optimal ML model and hyperparameters based on historical CuSCN performance data, reducing the time and expertise required to build high-performing models. In this study, AutoML generated configurations that reduced degradation rates by 13%, thereby extending the projected lifespan of tandem cells by several years [7]. AutoML’s ability to automate model selection offers immense potential in material science, particularly where rapid innovation cycles are needed.

Comparative insights and methodology analysis: The diverse ML methodologies reviewed demonstrate distinct strengths and limitations. While DNNs offer robust insights into interface compatibility for tandem structures, they demand high computational resources. Conversely, SVMs and Decision Trees, which require fewer resources, are effective for stability optimization and classification tasks, respectively. Reinforcement Learning’s adaptability to dynamic changes makes it suitable for environmental stability improvements, essential for real-world deployment of CuSCN-based cells. CNNs are particularly well-suited for applications where imaging data informs material resilience, whereas ensemble techniques such as Gradient Boosting prove valuable in optimizing light absorption metrics by leveraging varied dataset sources.

The comparative study of methodologies reveals key insights into the relative strengths of each ML approach. Supervised learning models, such as decision trees and SVMs, offer resource-efficient predictions with high accuracy rates, especially useful in the early screening stages of material selection. However, these models may lack the adaptability necessary for real-time environmental optimizations that are feasible with reinforcement learning and CNNs.

Hybrid approaches that integrate reinforcement learning with ensemble methods (like gradient boosting) stand out for their adaptability. For instance, Wang, et al. (2024) demonstrated that gradient boosting’s predictive capacity for light absorption, coupled with reinforcement learning’s adaptability to environmental changes, created a robust model with an unprecedented 18% light absorption improvement. This hybrid approach exemplifies the synergy possible when combining ML techniques, offering enhanced performance metrics for stability and efficiency.

CNNs and AutoML methods each bring unique contributions: CNNs enable precise, image-based analysis of microstructural resilience, making them ideal for materials that endure high thermal stress. AutoML, on the other hand, optimizes model selection without intensive resource requirements, demonstrating utility for rapid configuration testing. These findings suggest that while AutoML can offer scalable solutions, CNNs may be more suited to advanced research phases focused on resilience.

The implications of machine learning in this field go beyond incremental efficiency gains. By enabling rapid and accurate material selection, ML reduces the trial-and-error approach that traditionally delays technological advancements in solar cell design. Studies using reinforcement learning, CNNs, and AutoML exemplify ML’s potential to revolutionize tandem solar cells, particularly CuSCN-based structures, by enhancing their resilience against environmental stressors while optimizing light absorption and efficiency.

Moreover, these findings point to potential applications in scalability for CuSCN-perovskite layers, as models become faster and more precise in predicting optimal configurations. With the ability to automate material selection and fine-tune layer compatibility, ML supports the push toward commercial viability for tandem solar cells. The observed improvements in stability—such as reduced degradation rates—are particularly promising for regions with extreme weather, where conventional solar cells face significant durability challenges.

Limitations, challenges and future research directions: Despite the success of ML in material selection, challenges remain. The high computational demand associated with DNNs and CNNs can limit accessibility, particularly for large-scale implementation. Additionally, model interpretability poses a challenge, especially in complex models where understanding the decision-making process is crucial for scientific validation. Moving forward, integrating ML with high-throughput experimental methods could further expedite material discovery. Advances in reinforcement learning are likely to yield new possibilities in environmental resilience, while hybrid models combining multiple ML techniques may offer a balanced approach to optimizing both efficiency and stability.

Despite the progress, certain challenges persist in the application of machine learning for CuSCN-based tandem cells. Computational costs associated with models like CNNs and deep learning frameworks remain prohibitive for some laboratories, limiting accessibility. Additionally, as models grow more complex, interpretability becomes an obstacle; understanding the basis of predictions is essential for experimental validation and practical implementation. Addressing these issues requires advances in model interpretability and resource-efficient computation, potentially through the development of explainable AI (XAI) methods tailored for material science.

Machine learning (ML) has significantly impacted solar cell research, yet several drawbacks in previous applications have been identified. One major limitation is computational complexity, especially with deep learning models like CNNs, which require substantial computational resources for training and inference. Studies have shown that these models, while effective for image analysis in solar cell defect detection, can be prohibitively expensive for smaller research labs without access to high-performance computing (Khan, et al. 2020). This computational demand can slow down the iterative process of model training and optimization, especially when dealing with large datasets or when real-time processing is required.

Another significant challenge is overfitting, particularly in supervised learning scenarios where models are trained on limited datasets. Overfitting occurs when models learn the noise in the training data rather than the underlying pattern, leading to poor generalization on new, unseen data. This has been a noted issue in models predicting solar cell efficiency, where the high variability in material properties can lead to models that over fit to the training data [1]. Techniques such as regularization, cross-validation, and the use of ensemble methods like random forests have been employed to mitigate this, but the balance between model complexity and generalization remains a nuanced challenge (Bhatti, et al. 2022).

Data quality and quantity also pose significant limitations. ML models heavily rely on the quantity and quality of the data they are trained on. In solar cell research, obtaining large, well-annotated datasets can be costly and time-consuming, which affects the robustness of ML applications. For instance, unsupervised learning methods like clustering are especially sensitive to the quality of data, where poor data can lead to misleading patterns or clusters (Han, et al. 2021).

Furthermore, the transferability of ML models from lab to real-world environments is not always straightforward. Models trained on controlled experimental data might not perform as expected under the varied conditions of outdoor environments, where factors like temperature, humidity, and light intensity fluctuate. This issue is highlighted in studies attempting to predict energy yield or stability over time, where the models show significant variance when applied outside the lab conditions [29].

Another aspect is the interpretability of ML models, particularly deep learning models which are often criticized for being “black boxes”. This lack of transparency can be a barrier in solar cell research, where understanding the relationship between materials and performance is crucial for further development. Recent efforts in explainable AI (XAI) aim to address this, but progress in this area is still evolving [28].

Lastly, parameter sensitivity in ML models can lead to variations in predictions. Models might be highly sensitive to changes in input parameters, which in practical applications can lead to inconsistent results if those parameters are not precisely controlled. This is particularly relevant in reinforcement learning applications for process control, where slight variations in environmental conditions or material properties can significantly affect outcomes [7].

These limitations suggest that while ML has brought advancements to solar cell research, there is a continuous need to refine these models to handle real-world variability, reduce computational demands, and enhance model interpretability and robustness. Addressing these challenges will be crucial for the next generation of ML applications in solar technology.

Future research could benefit from further exploration of hybrid ML models, particularly those that integrate reinforcement learning with predictive ensemble methods. As hybrid models show promise in balancing performance with adaptability, refining these methods could bridge gaps in both stability and efficiency. AutoML also holds significant potential for expansion, as it can democratize access to ML-enhanced material discovery, providing resource-constrained laboratories with robust model-selection capabilities.

Additionally, there is a pressing need for standardized datasets across studies to improve model training and benchmarking. Currently, disparate datasets limit the comparability of results and hinder the refinement of ML models. Collaborative data-sharing initiatives between academic and industrial research groups could address this, creating a robust foundation for model development and validation.

Recent innovations in predictive modeling for solar cell stability and efficiency: ml-driven approaches for interface optimization

Machine learning’s role in predictive modeling has greatly enhanced the ability to forecast solar cell stability and efficiency, particularly in the interface optimization of CuSCN-perovskite tandem solar cells. ML-driven predictive models facilitate the identification of optimal configurations, fine-tune material selection, and assess long-term durability. This section delves into the latest advancements in predictive modeling, with a specific focus on interface optimization.

ML-driven interface optimization: Interface optimization is critical for tandem solar cell efficiency and stability, as the interfaces between CuSCN and perovskite layers significantly influence charge transport, light absorption, and overall energy conversion efficiency. Machine learning techniques, particularly predictive modeling, play a pivotal role in optimizing these interfaces, enabling researchers to preemptively address issues related to charge recombination, defect density, and interface degradation.